Six tips to ensure food processing safety

Food processing is crucial in delivering safe and quality food products to consumers. To achieve this, food processing facilities must adhere to specific guidelines. However, ensuring food processing safety requires a comprehensive approach that covers various aspects of the production process.

The following are six tips to help food processing facilities maintain high safety standards and protect consumers from potential risks.

1. Control pests

Pests significantly threaten food processing safety as they can contaminate the production environment and products. Implementing a robust pest control program is essential.

This includes regular inspections, effective preventive measures, and prompt actions to eliminate pests.

Employing techniques such as:

● Sealing entry points

● Implementing proper waste management

● Utilizing traps or baits can help prevent pest infestations

Regular monitoring and documentation of pest control activities ensure that potential risks are identified and addressed promptly, protecting the integrity and safety of the food processing facility.

Work with professional pest control experts who can guide and assist in identifying and eliminating pest infestations and ensure to use eco-friendly methods when dealing with pests.

2. Adhere to proper temperature control measures

Monitoring and maintaining temperatures throughout production is essential to prevent bacterial growth, preserve product quality, and increase shelf life. Temperature control procedures should be established for receiving, storage, processing, and shipping.

Regularly check the accuracy of temperature monitoring devices, such as thermometers and data loggers, through verification. It's also crucial to provide sufficient training to employees on temperature control protocols and the necessary corrective actions to take in case of changes.

3. Build a strong safety system

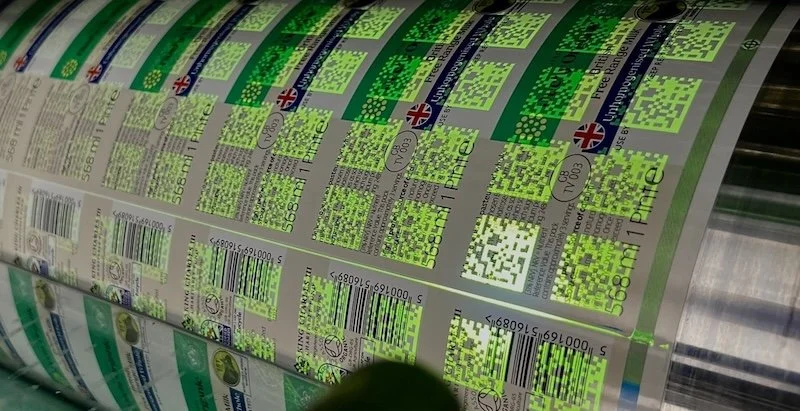

The foundation of safe food processing lies in establishing a robust safety system. This system should include essential practices like Good Manufacturing Practices (GMPs), Hazard Analysis Critical Control Point (HACCP) principles, and Standard Operating Procedures (SOPs).

Food X-ray systems are also powerful tools that aid in detecting foreign objects or contaminants in food products. These x-rays by TDI Packsys use advanced imaging technology to identify potential hazards, such as glass, metal, stones, or plastic, that may inadvertently enter the production process.

4. Conduct regular equipment maintenance

Regular maintenance, inspection, and adjustment of processing machinery, scales, and measuring devices are necessary to ensure accuracy and reliability. Faulty equipment can compromise the safety and quality of food products.

Establishing a preventive maintenance program, documenting maintenance activities, and promptly addressing equipment issues are key steps to prevent unexpected breakdowns. It can also help reduce the risk of contamination or product defects.

5. Regularly train your staff

It is essential to provide comprehensive training programs to all employees, covering topics such as food handling practices, sanitation procedures, and the recognition of potential hazards.

Regular training sessions should be conducted to reinforce good practices and update employees on the latest food safety regulations and industry standards.

Investing in staff training creates a food safety culture and ensures all employees have the knowledge and skills necessary to maintain a safe and hygienic processing environment.

6. Ensure proper waste management

Effective waste management practices involve properly disposing of organic and non-organic waste materials generated during processing.

Regular waste removal, segregation, and appropriate storage of waste are essential to prevent the attraction of pests and the growth of harmful bacteria. Implement waste management protocols that comply with local regulations and industry standards.

This includes training staff on proper waste handling procedures and providing clearly labeled waste disposal bins.

Endnote

Safety should always come first in food processing. By following these six essential tips, food processing businesses can prioritise safety, comply with regulations, and deliver high quality products to consumers.

Building a strong safety system, maintaining cleanliness, monitoring temperature, ensuring well maintained equipment, and selecting reliable suppliers are all crucial steps in achieving food processing safety.

Prioritising safety protects consumers and enhances trust and competitiveness in the industry.

Continue reading…