How is biologics development and manufacturing being redefined?

The development and manufacturing of biologics, which include complex therapeutic proteins, monoclonal antibodies, and vaccines, are undergoing significant transformations.

As the demand for these advanced treatments grows, new innovations and approaches are redefining how biologics are developed and produced.

This article explores the latest trends in biologics development and manufacturing, highlighting the technological advancements and the role of specialised organisations in driving these changes.

The growing importance of biologics

Biologics represent a significant advancement in modern medicine, offering targeted therapies for a range of diseases, including cancer, autoimmune disorders, and genetic conditions. Unlike traditional small molecule drugs, which are chemically synthesised, biologics are produced using living cells.

This makes their development and manufacturing processes inherently more complex and demanding.

Increasing Demand For Biologics

The demand for biologics is increasing due to their effectiveness in treating complex conditions that were previously difficult to manage with conventional drugs.

This growing demand is pushing the boundaries of traditional manufacturing techniques and necessitating the adoption of new technologies and approaches to scale up production and meet market needs.

For more insights into the impact of biologics on healthcare, you can visit Science Daily.

Innovations in biologics development

Advanced Cell Line Development

One of the critical aspects of biologics development is cell line development. This process involves creating and optimizing cell lines that can efficiently produce the desired therapeutic proteins.

Recent advancements in genetic engineering, such as CRISPR-Cas9, have revolutionised cell line development by allowing precise modifications to the genetic material of cells. This has led to the creation of high yield, stable cell lines that are crucial for the consistent production of biologics.

Organisations specializing in biologics development, such as Wheeler Bio, leverage these advanced techniques to ensure efficient and reliable production. Their expertise in cell line development helps biopharma companies bring new therapies to market more quickly and efficiently.

Innovative Bioprocessing Techniques

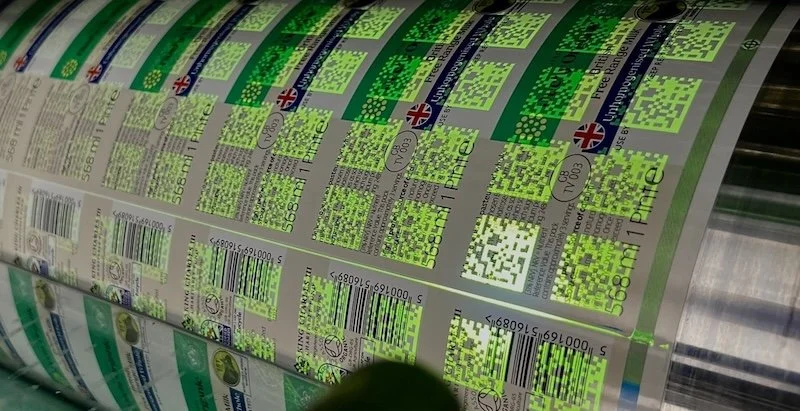

Bioprocessing is the backbone of biologics manufacturing, encompassing the various stages of producing and purifying biologic products. Innovations in bioprocessing techniques, such as continuous manufacturing and single-use technologies, are transforming how biologics are produced.

● Continuous manufacturing: This approach involves the continuous flow of materials through the production process, as opposed to traditional batch processing. Continuous manufacturing enhances production efficiency, reduces downtime, and ensures more consistent product quality.

● Single use technologies: These systems use disposable components, such as bioreactors and filtration units, which eliminate the need for cleaning and sterilisation between production runs. This reduces the risk of contamination and increases overall production flexibility and efficiency.

For more updates on the latest bioprocessing innovations, check out TechCrunch.

Ensuring quality and compliance

Advanced Analytical Testing

Maintaining the highest quality standards is critical in biologics development and manufacturing.

Advances in analytical testing methods, such as high-resolution mass spectrometry and next generation sequencing, provide detailed insights into the molecular composition of biologics. These techniques help ensure that biologic products meet stringent regulatory requirements for safety, efficacy, and purity.

Navigating Regulatory Requirements

Navigating the complex regulatory landscape is a significant challenge in biologics development. Companies must comply with stringent guidelines set by regulatory bodies such as the FDA and EMA to ensure that their products are safe and effective for patient use.

CDMOs play a crucial role in providing regulatory support, helping biopharma companies prepare and submit the necessary documentation for regulatory approval.

The role of CDMOs in biologics manufacturing

Contract Development and Manufacturing Organisations (CDMOs) are essential partners in the biologics industry, offering a wide range of services that support the development and production of biologic drugs.

These organisations provide expertise in areas such as process development, scale-up production, and quality control, enabling pharmaceutical companies to bring biologic therapies to market more efficiently.

Comprehensive Services And Expertise

CDMOs like Wheeler Bio offer comprehensive services that cover the entire lifecycle of biologics, from early-stage development to large-scale manufacturing. Their state-of-the-art facilities and advanced technologies ensure that biologic products are developed and produced to the highest standards of quality and compliance.

By partnering with CDMOs, biopharma companies can leverage specialized knowledge and resources to overcome the complexities of biologics manufacturing. This collaboration is critical for accelerating the development process and ensuring the successful commercialisation of biologic therapies.

Trends shaping the future of biologics manufacturing

Personalised Medicine

Personalised medicine is an emerging trend that involves developing therapies tailored to the individual needs of patients. Biologics play a key role in this approach, offering treatments that are specifically designed based on a patient’s genetic profile and disease characteristics.

CDMOs are adapting their services to support the production of personalized biologics, which often require smaller, more flexible production runs.

This includes developing scalable processes and leveraging advanced cell line development techniques to produce customised therapies that meet the unique requirements of personalised medicine.

Sustainable Manufacturing Practices

Sustainability is becoming increasingly important in biologics manufacturing, with a growing focus on reducing the environmental impact of production processes.

Companies are adopting sustainable manufacturing practices such as using renewable energy sources, minimising waste, and implementing green chemistry principles.

CDMOs are leading the way in integrating sustainable practices into biologics manufacturing, ensuring that the production of biologics is both environmentally responsible and economically viable.

This commitment to sustainability aligns with the increasing demand for greener healthcare solutions and contributes to the long-term viability of the biologics industry.

For insights into the future of sustainable manufacturing practices, visit Nature.

Challenges and opportunities in biologics development

Addressing Technical Challenges

Despite significant advancements, biologics development and manufacturing still face several technical challenges.

These include optimising cell line development, improving process efficiency, and ensuring the stability of biologic products. Ongoing research and development efforts are focused on overcoming these challenges and enhancing the production of biologics.

CDMOs are at the forefront of these efforts, investing in new technologies and methodologies to drive innovation and improve the efficiency and scalability of biologics manufacturing.

Expanding Access To Biologics

Expanding access to biologics is a key priority for the healthcare industry. Advances in manufacturing technologies and process optimization are making it possible to produce biologics at a lower cost, increasing their availability to patients around the world.

Innovators in the field are also exploring new delivery methods and formulations that improve the efficacy and convenience of biologics, making them more accessible to diverse patient populations.

CDMOs play a crucial role in these efforts by providing the expertise and infrastructure needed to produce biologics efficiently and cost effectively. Their contributions are essential for ensuring that all patients have access to the life saving therapies that biologics offer.

Conclusion

Biologics development and manufacturing are being redefined by a combination of technological advancements and innovative approaches.

By leveraging these advancements, the biologics industry is better equipped to meet the growing demand for effective and personalised therapies, ultimately improving patient outcomes and advancing healthcare.

Continue reading…