RELEX Solutions: retailers must transform approaches to supply chain management by embracing AI and ML

A new study by RELEX Solutions reveals that, while 57% of retailers and CPG companies plan to invest in predictive and generative AI in the next three to five years, AI and machine learning ranked just fifth in importance for overall technology spend behind enhancing e-commerce capabilities, improving inventory management, demand forecasting, and leveraging data analytics.

The report was conducted by Researchscape and surveyed 285 retail, CPG, and wholesale leaders globally.

Overall, respondents rated rapidly shifting consumer demand volatility (55%), global events and disruptions (50%), and inaccurate sense of customer specific demand (43%) as the biggest threats to improving supply chain efficiency and accuracy over the next three years.

94% of respondents also said they have been impacted by social media influencing or "de-influencing" over the last 12-24 months – another sign that anticipating and sensing demand surges across all channels will be especially critical to success.

🚀 Learn more about the untapped potential of AI in retail & CPG, the impact of social media, and the cost of poor collaboration in the first RELEX State of Supply Chain 2024: Retail and CPG Dynamics report

— RELEX Solutions (@RelexSolutions) April 8, 2024

Read more: https://t.co/252NFJoCkk#SupplyChain #Retail #CPG #AI

Retailers are rearchitecting supply chains to navigate evolving consumer expectations, channel shifts, disruptions and uncertainty. Key findings include:

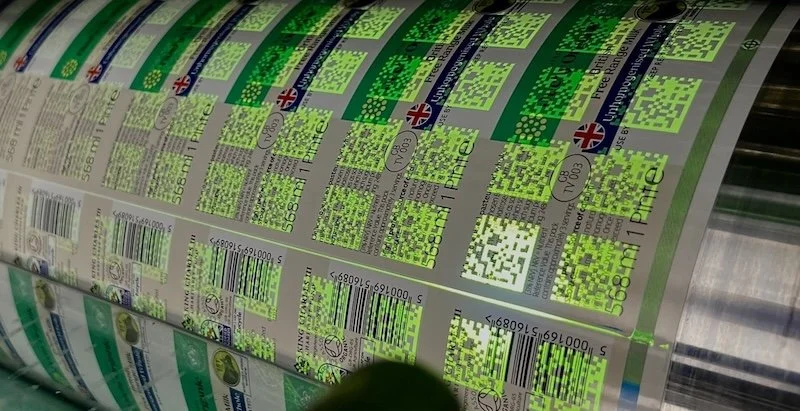

The top three most essential capabilities for retailers to manage consumer demand and inventory levels are real-time inventory visibility (45%), customer demand sensing (45%), and inventory optimisation tools (43%)

Another 59% of respondents are expanding omni-channel options from some locations to accommodate shifting consumer delivery preferences, tackling the need to evolve to changing consumer preferences

More than half (53%) are expanding supplier base/sourcing options to add sourcing redundancy to diversify and mitigate risks associated with disruptions

Integrated supply chain planning capabilities are critical for CPGs to balance volatility and retail collaboration while expanding consumer touchpoints. However, change is difficult given complex legacy constraints and trade-offs required across disconnected organisations.

Key findings include:

79% of CPGs report day-level planning is crucial for accurately forecasting and responding to consumer demands

32% say disconnected planning across different teams, systems, and regions, and 27% reporting slow and misaligned planning cycles and levels are impacting the synchronisation of end-to-end value chain planning and execution

Supply variability, including materials shortages and production disruptions, impact 82% of CPGs’ ability to meet order expectations

To navigate macro-economic factors like inflation, CPGs are focused on adjusting inventory and production strategies via monitoring demand signals (48%), building in safety stock or keeping higher inventory levels (22%), and inventory turnover as part of their inventory and production strategies

"The retail and CPG industries continue to face complex, global challenges that require actionable insights to accurately predict, anticipate, and manage consumer demand,” says Laurence Brenig-Jones, VP of Strategy & Marketing, RELEX Solutions.

“To thrive in this new reality, companies must fundamentally transform their approach to supply chain management by breaking down silos, embracing new technologies like AI and ML, and fostering a culture of collaboration and agility.”

“The winners will be those that can achieve resilience and flexibility, to sense and respond to disruptions and opportunities in real-time, and continuously adapt their strategies in the face of change.”

“With the right mindset, tools, and partners, retailers and CPGs can build the supply chains of the future and unlock new levels of growth and profitability.”

Continue reading…