Check out this article on optimising fashion retail with end-to-end software solutions

Fashion retail was once a relay race of disconnected hand-offs: design files shuttled to planning, purchase orders re-keyed into finance, and Point of Sale data reconciled days - sometimes weeks - after shoppers had already moved on to the next trend.

That latency inflates inventory, erodes margins, and leaves brands guessing which collection items resonate in real time. A new generation of end-to-end software is rewriting the playbook. By knitting enterprise resource planning, product lifecycle management, omnichannel order orchestration, and data analytics into a single digital spine, retailers can replace lagging indicators with live insight - and move from reactive firefighting to proactive optimisation.

From Software Silos to Unified Architecture

Legacy fashion systems evolved in isolation: accounting ran on one platform, warehouses on another, e-commerce on a third. Each produced its own “version of truth,” forcing teams to reconcile numbers before making even routine decisions. End-to-end suites collapse those silos by sharing a common data model. When a style code enters the master catalogue, every downstream module - allocation, replenishment, customer service - reads from the same record.

The moment a shopper buys the last size-M jacket online, for example, inventory updates everywhere, preventing double-selling and directing replenishment to the correct node. Synchronised data not only reduces errors; it frees planners to focus on strategy instead of spreadsheet triage.

ERP Systems as the Operational Core

At the heart of any unified stack sits the ERP, the ledger of inventory, cost, and cash. Modern apparel ERP systems are built specifically for style-colour-size complexity: they store season codes, manage pre-packs, and calculate landed cost across multistage sourcing.

Because the ERP shares an API layer with design and commerce tools, a change to fabric yield or supplier terms propagates instantly to gross-margin forecasts - no manual re-entry required. Support for mobile scanning and RFID brings real-time visibility onto the sales floor and into the stockroom, cutting the “blind spots” that drive safety stock.

Integrating Front-End Experience With Back-End Execution

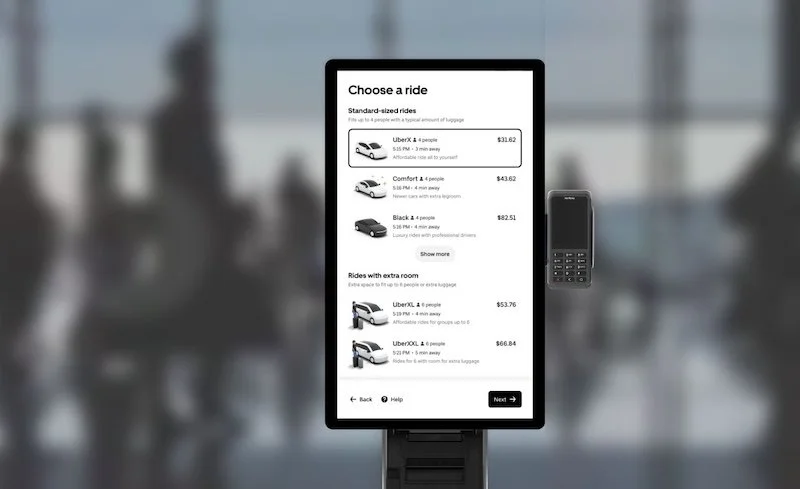

A consumer rarely sees the ERP, yet it charts their purchase journey. When a digital clienteling app pulls stock availability, it queries the inventory service published by the core system; when a buy-online-pick-up-in-store order prints in the stockroom, fulfilment rules - ship-from-DC versus pick-from-floor - are driven by the same source.

Connecting those dots depends on middleware that translates business logic into real-time APIs. In practical terms, an associate armed with a tablet can promise next-day delivery on an out-of-stock colour because the application is reading warehouse inventory to the minute, not yesterday. As shoppers demand hybrid journeys - reserve online, pay in app, return in store - this tight integration shifts the conversation from “Can we do it?” to “How well can we do it?”

Building a Resilient, Sustainable Supply Chain

The pandemic exposed how brittle global sourcing had become; fashion’s next challenge is to build supply chains that flex without waste. McKinsey’s latest State of Fashion report predicts retailers will accelerate nearshoring and invest in technology that cuts excess inventory while mitigating shortages. End-to-end platforms support that shift by linking demand signals directly to factory planning.

When velocity on a key style spikes, real-time PoS data updates open-to-buy calculations inside the ERP, which in turn issues component forecasts to suppliers through the same portal. Sustainability modules track carbon and water footprints at SKU level, letting brands throttle production to actual demand and publish progress to regulators and consumers alike.

Change Management: People Make Software Work

The promise of integrated tech can falter if organisational habits lag behind. Merchandisers accustomed to month-old sell-through must learn to act on daily dashboards; store teams need confidence that mobile counts reconcile with head office numbers; executives must trade gut instincts for scenario modelling.

Successful roll-outs pair platform training with new KPIs - decision cycle times, forecast accuracy, gross-margin return on inventory - to reinforce data first behaviour. When every department measures its output against live system feedback, continual improvement becomes self-reinforcing.

Conclusion

Timing and honesty are the lifeblood of fashion retail-succeed there and most things will follow. A single, modern platform weaves together ERP, planning, fulfilment and analytics through clean APIs, replacing patchwork tools. With all data united, costly errors fade, AI turns numbers into forecasts, and joined workflows let brands greet shoppers wherever they want to buy.

When economic storms and climate scrutiny grow louder, retailers who back a cohesive digital backbone move quicker, waste less and please customers far more than rivals still shuffling spreadsheets and outdated silos. In a world that never stops shifting, the sharpest edge comes from knowing in real-time what is happening from the design studio to the doorstep-and having an agile system that can act on it.

Continue reading…