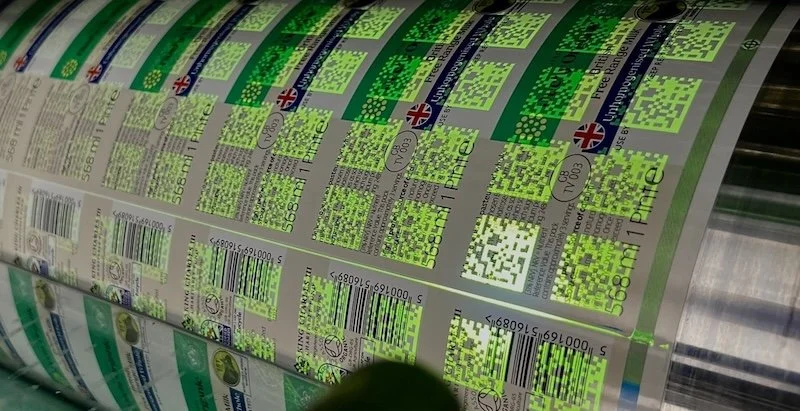

FLX Logistics taps robotics and digital twin technologies to boost warehouse management with DexoryView solution

Dexory has deployed DexoryView, its AI and robotics solution, at the warehouse facility of FLX Logistics, part of the Freshlinc Group, in Peterborough, United Kingdom.

“We are always looking for ways to enhance efficiency and accuracy across our operations,” says Sam Goodger, General Manager for the FLX Logistics site at Peterborough.

“Using DexoryView from the outset at our new facility provides us with unparalleled real-time data on stock accuracy that empowers our team to drive the business forward.”

In a recent implementation, at FLX Logistics’ new facility, spanning 140,000 square feet and housing products ranging from diverse food products, raw materials and finished goods, Dexory unveiled its DexoryView solution, featuring autonomous mobile robotics (AMRs) and an integrated digital twin.

FLX Logistics was able to generate data from the outset to ensure it had stock accuracy from the opening of the new warehouse.

This combines with having access to real-time data of the warehouse on an ongoing basis.

“We are thrilled to be working with FLX Logistics in revolutionising their warehouse operations,” says Oana Jinga, Chief Commercial and Product Officer and Co-Founder at Dexory.

“Having implemented DexoryView from the outset shows that FLX Logistics is a forward thinking business and sees the benefit in utilising real-time data and insights to better drive efficiency across its operations.”

“We have already seen the company use the data to effectively manage and transform its day-to-day operations thanks to the insights they are able to glean from DexoryView.”

Continue reading…