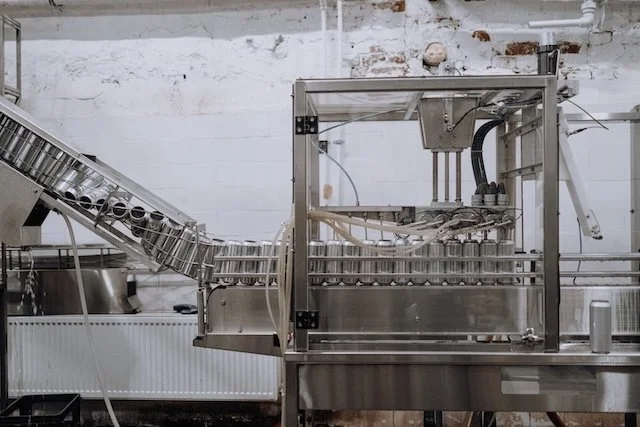

How to integrate metal detectors into existing food retail operations without disrupting workflow

Heavy metal detection is essential in food retail operations for ensuring product safety and quality regulations. However, many retailers worry that implementing new technology might slow down operations and complicate their workflow.

With the right planning and staffing involvement, metal detection can become an easy part of daily operations. Here is a guide on how to integrate detection into existing processes without causing delays.

Photo credits: Pexels.

1. Understand Your Retail Workflow Before Installing Metal Checkers

Analyzing your workflow and why you need metal detectors is important before installing the technology. This starts with considering the food products you retail or process and mapping on how products move from receiving to customers.

You should also assess the operating conditions like temperature, cleanliness, and other safety measures. Knowing staff responsibilities and existing quality control procedures enables you to identify where detectors will add the most value.

Consulting frontline staff is equally crucial. They often know where workflow interruptions occur and can tell if the technology may either worsen or improve. Moreover, conduct a feasibility study to understand the technical requirements of the product line. These include speed, conveyor belt width, and space available. By fully assessing operational flow, you can determine the optimal integration method and avoid unnecessary disruptions.

2. Position Metal Detectors at Critical Control Points

Critical Control Points (CCPs) are stages in the retail process where contamination is most likely to occur. They include product formulation, testing, heating, and cooling points. Grinding or blending areas are also dangerous points that can introduce heavy metals to food.

Strategically placing a metal detector at these points ensures contamination is eliminated or reduced to acceptable levels before reaching customers. However, you should consider the technology layout and traffic low.

In areas with high traffic, choose compact or tunnel-style checkers that can check items without slowing down movement. Installing food-grade metal detectors near slicing machines or packaging units is also important if you have an in-house kitchen.

This helps capture metal fragments generated by equipment wear and tear. Proper CCP placement enhances safety and minimises redundant checks. As a result, the inspection will occur exactly where it is more needed, which improves efficiency and reduces workflow interruptions.

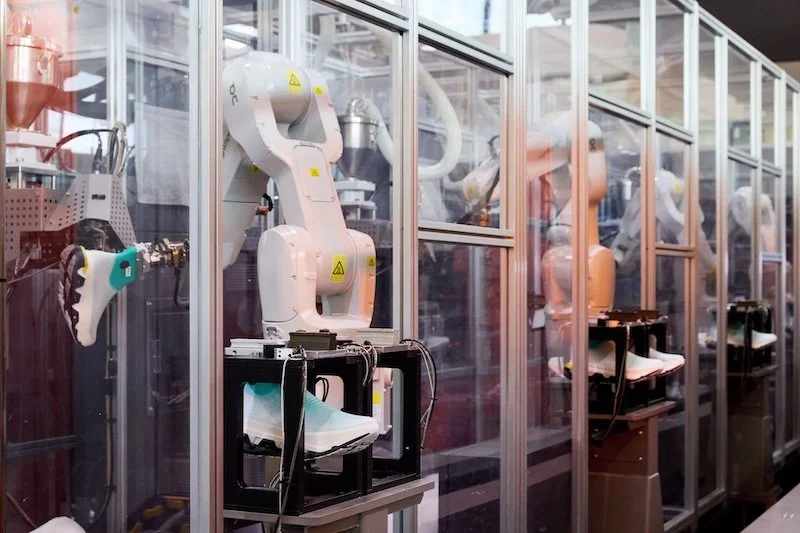

3. Use Smart Automation and Live Monitoring

Food metal detection systems do a good job of ensuring product safety. However, continuous monitoring is needed to make sure they work effectively without giving false alarms. This includes installing smart detectors with automation features and real-time monitoring tools to maintain speed and accuracy.

For instance, automated checkers have rejection mechanisms, like pneumatic pushers or drop-down reject bins, that remove contaminated items instantly without requiring manual intervention. This reduces delays and prevents staff from having to stop operations to check products.

Live monitoring tools can work effectively when added to the existing point of sales, inventory, or quality management systems. These digital dashboards automatically collect detection data, track performance trends, and notify supervisors of irregularities.

This streamlines reporting for compliance purposes and helps identify recurring sources of contamination. Cloud connectivity also allows supervisors to monitor multiple retail locations simultaneously. This ensures consistency while keeping workflow disruption to a minimum.

Endnote

Integrating metal checkers into food retail operations is achievable with a well planned approach. Retailers can improve food safety without reducing efficiency by understanding their business needs and identifying critical control points.

However, it is important to be aware of issues like technical compatibility and cost factors. Working with a team of experts is also vital to getting customised solutions for your retail needs.

Continue reading…